FLAME AND INDUCTION-HARDENING STEELS

These hot-rolled carbon and alloy steels are delivered in bars and coils.

In case of low stress level, normalized or quenched and tempered carbon steels are used, while for high stress levels the use of quenched and tempered alloy steels is recommended.

Flame and induction-hardening steels are carefully prepared in order to obtain a constant level of chemical elements, especially with regard to carbon, which is fundamental in guaranteeing hardenability.

Designers select the right steel on the basis of the stresses and the dimensions of the parts, starting from the grade C43 up to 40NiCrMo3.

Before surface hardening these steels are generally normalized and quenched and tempered, since the components must have a good toughness even ate the core.

Peeled products are recommended in order to achieve excellent results and to avoid decarburization that reduces surface hardness.

Flame hardening and more commonly induction hardening is used to achieve surface hardening. Heating is sudden and cooling is equally strong, therefore stress relieving (140-180 °C) is recommended after hardening. The penetration of induction hardening into the parts depends on the medium or high frequency. Lower frequency allows for a better penetration.

In some cases, where the treated areas are too small or access is difficult, laser hardening may be used. This practice is usually very fast, causes minimum distortions and results in high surface hardness.

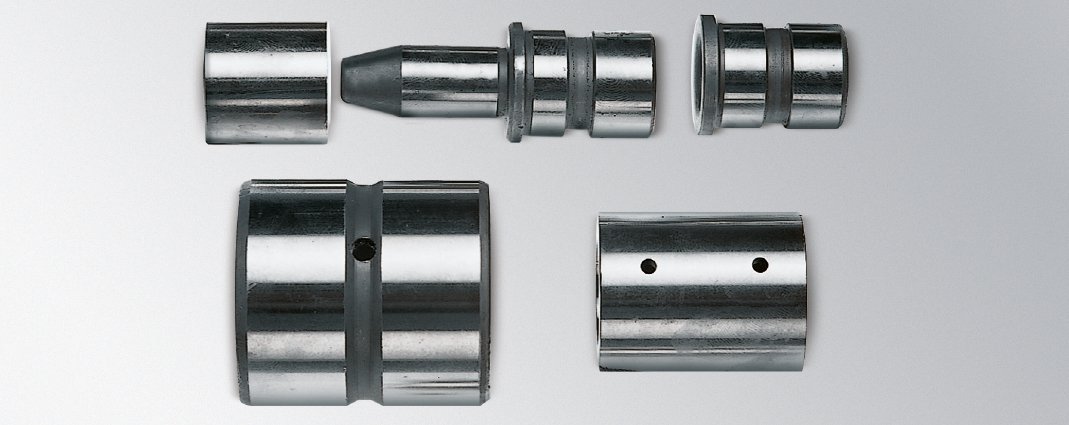

Il prodotto più comunemente ricavato con questi acciai va dagli alberi a camme e a gomito, a perni, ingranaggi, maglie in genere, viti senza fine, ruote dentate ecc.