NON DESTRUCTIVE TESTS (NDT)

The Lucefin Group is equipped to carry out a complete range of non-destructive tests, with expert and qualified personnel in accordance with the EN ISO 9712 standard.

NDT are divided into two categories according to the position of the defect to be detected:

Surface controls and Volumetric controls

SURFACE CONTROLS

Visual testing VT

The operator checks for the presence of surface defects by visual examination. The main advantages: it is cheap and simple and, for some products such as profiles, it is the only one applicable.

Penetrating liquids PT

This control exploits the liquid nature of the contrast medium for the detection of surface defects. There are no limitations on the geometry of the piece, moreover it is possible to carry it out even on large pieces.

Reference standard: EN ISO 3452-2013.

Magnetic particle testing MT

This control uses the magnetic nature of the control powders that settle in the vicinity of the defect after magnetization. Again, there are no limitations on the geometry of the piece provided that the product to be controlled is ferro-magnetic; it can also be done on large pieces; moreover, it can also detect subsurface defects closed on the surface.

Reference standard: EN ISO 9934.

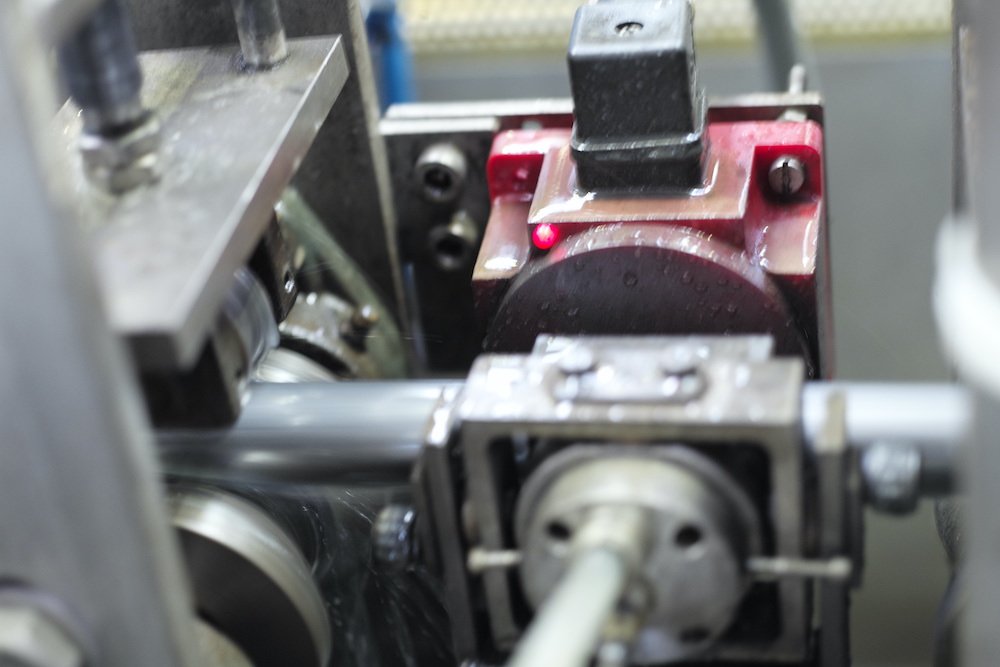

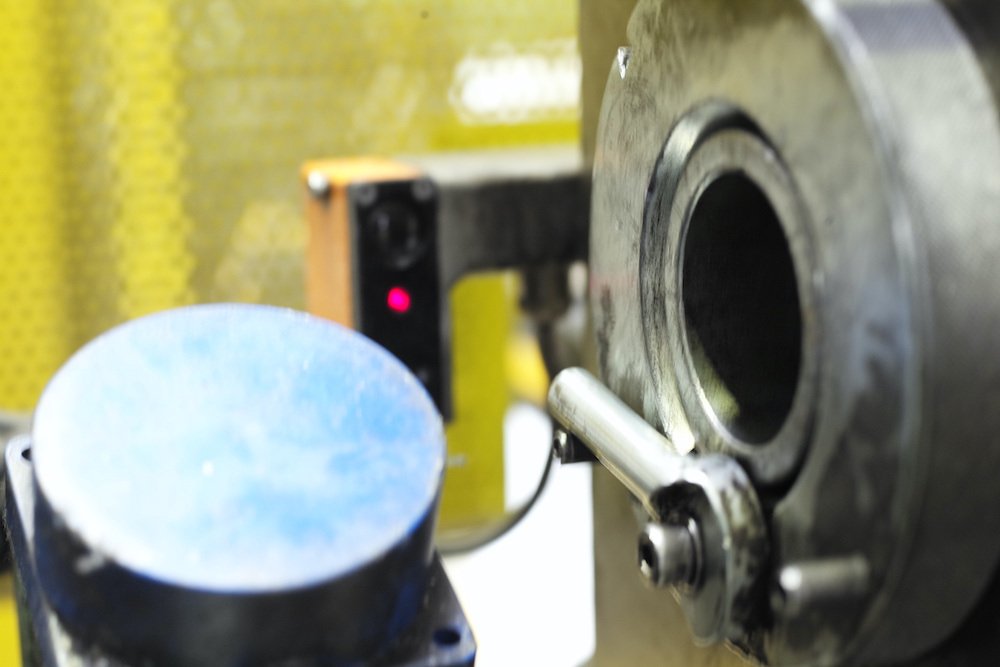

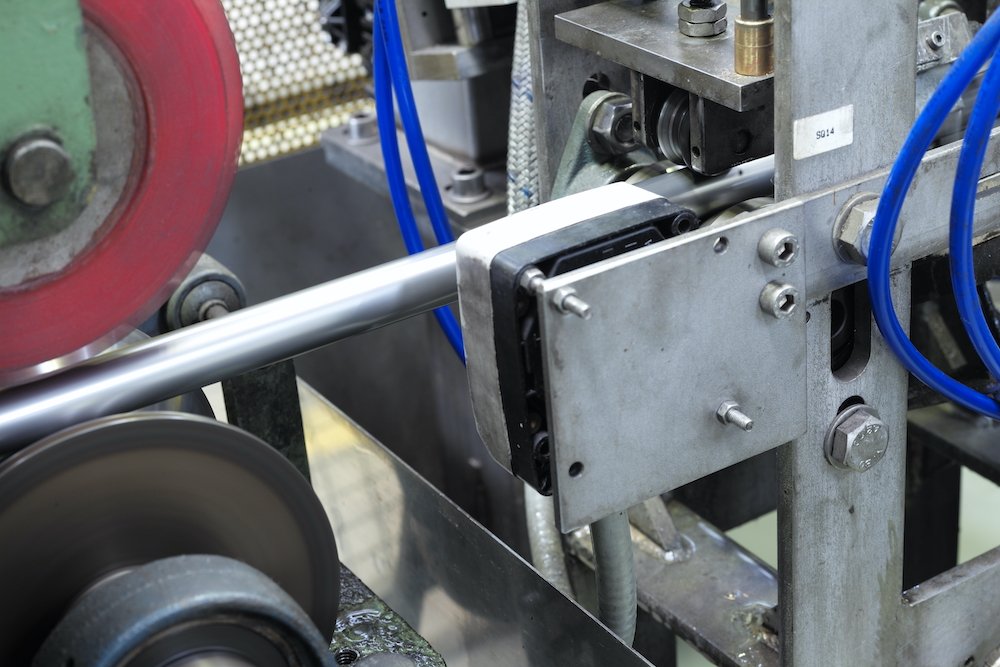

Eddy Current ET

This control uses induced currents generated by the magnetic field of a powered coil

to current.

The presence of any discontinuity modifies the intensity and the path of the induced currents and therefore the impedance of the circuit, the variation of which is an indication of possible defects. The eddy current method is regulated by ISO EN 15549 standard. The Lucefin Group is equipped with rotating head probes (Circograph®) and static coil (Defectomat®).

VOLUMETRIC CONTROLS

Ultrasonic testing UT

Inspection using ultrasound is a non-destructive method in which sound waves are introduced into the material to be examined, in order to highlight internal defects., measure the distance and the size of the defects.

This type of control allows to size the defect; moreover, it can be carried out on all round, flat, square and hexagonal sections with 100% coverage.

The check can also be carried out on large pieces.

Phased Array Ultrasonic Testing

The Group is equipped with automated systems with ROWA® for UT control with phase – array technology. This is a fast and accurate check.

Antimixing

Anti-mixing control is a non-destructive control aimed at avoiding mixing of materials, and is based on the principle of electrical conductivity.

© 2025 All rights Reserved – LUCEFIN S.P.A. via Ruc 30 Esine (BS) ITALY P.IVA IT01535340986 – lu*****@*******il.it – co*****@*****in.com